From residual textiles to interior solutions – «ABSORBER RECYCLED»

Sustainability begins with the intelligent use of existing resources. With our recycling process for acoustic panels, we demonstrate how high-quality production residues can be transferred into a new life cycle.

EXCLUSIVELY AVAILABLE IN SWITZERLAND, GERMANY AND AUSTRIA.

Innovation meets sustainability: The journey of ABSORBER RECYCLED

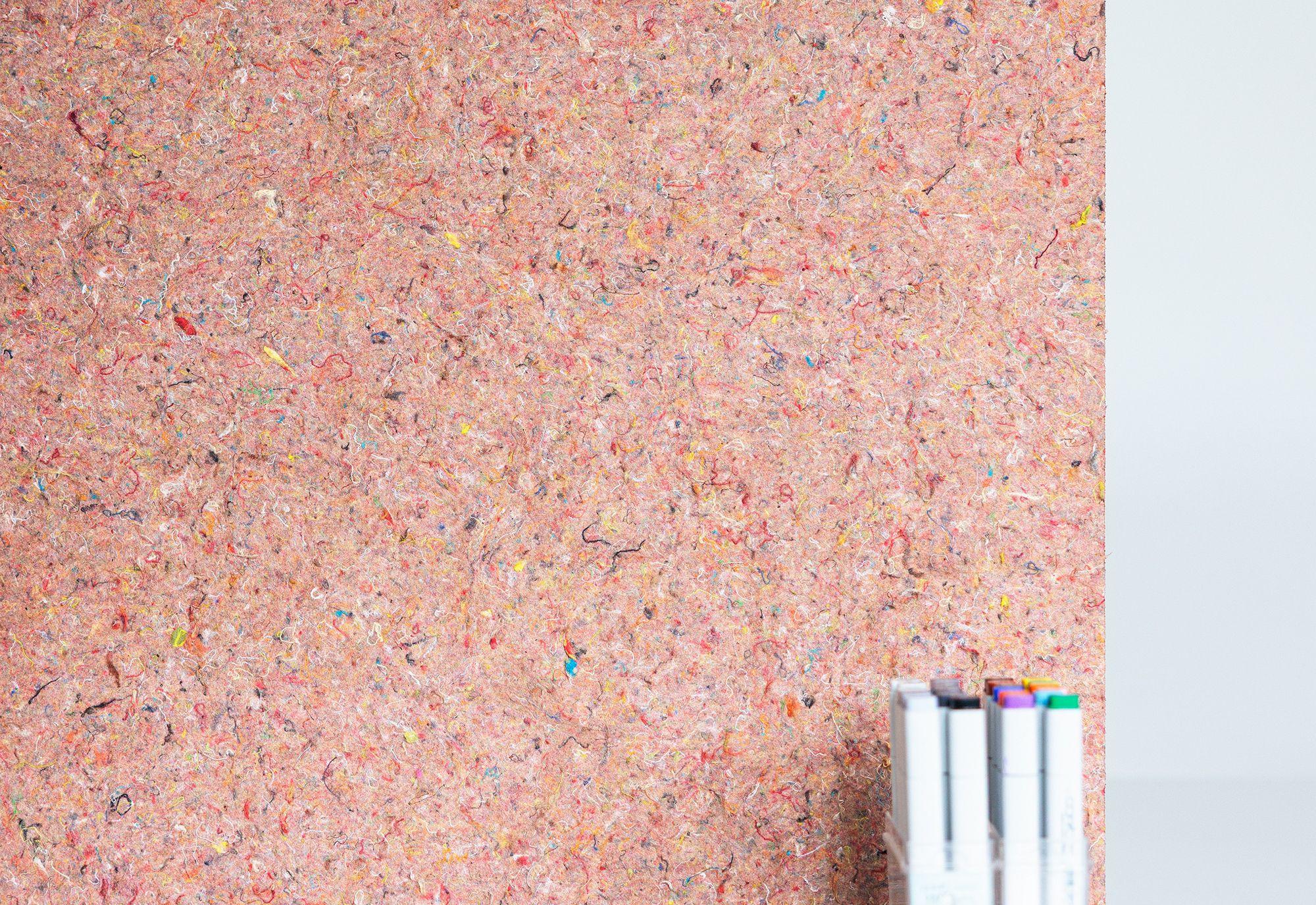

With ABSORBER RECYCLED, we demonstrate how production waste can be transformed into something new and valuable. The innovative recycling process converts sorted Trevira CS textile waste into stable acoustic panels – a sustainable solution that combines functionality and design. The following insight shows the journey from fibre mixture to precise laser cutting.

In conversation with Philppe Baumann

-

Mr Baumann, Création Baumann is a pioneer in the field of textile acoustic solutions. What motivated you to establish a sustainable circular process in this area with ABSORBER RECYCLED?

Sustainability has always been a core value of our family-run company. We are aware that textile raw materials are finite, so it was only logical for us to take the next step and launch ABSORBER RECYCLED, a fully thought-out, sustainable circular process for acoustic solutions. The inclusion of high-quality pre-consumer textile waste in our own factory enables us to keep valuable resources in circulation. This creates an ecologically sustainable, functional solution that also sets new standards in terms of design.

-

What does it mean for you as a textile manufacturer to take responsibility for the entire product life cycle – from production to recycling?

As a textile manufacturer with over 130 years of experience, we see it as our responsibility to act sustainably throughout the entire life cycle of our products. This begins with the selection of durable materials, continues with energy-efficient and locally sourced production processes, and extends to innovative recycling solutions such as ABSORBER RECYCLED. We want to offer products that impress with their good design, functionality and environmental compatibility – while at the same time conserving resources and minimising our ecological footprint.

-

The new absorber panels are made from sorted Trevira CS textile waste. What challenges had to be overcome on the way to achieving this fully textile recycling process?

The path to a functioning, single-type recycling process was technologically demanding. It was a challenge to develop processes for reliably collecting high-quality residual Trevira CS textiles, separating them into single types and shredding them to fibre size in a multi-stage process. Mixing with melt fibres and the subsequent pressing process to produce stable, acoustically effective panels required many tests and adjustments until the result met our high standards of quality, durability and design.

-

Création Baumann develops many solutions at its Langenthal site. What role does local production play in your sustainability strategy?

Our deep roots in the Langenthal region are a key component of our sustainability strategy. Short transport routes, transparent production processes and close integration of development and manufacturing enable us to produce efficiently, in an environmentally friendly and socially responsible manner. At the same time, we are strengthening Switzerland as a centre of innovation while ensuring the highest quality standards. The further processing of ABSORBER RECYCLED panels at the Langenthal plant is a commitment to a sustainable, future-oriented corporate policy.

-

How are architectural firms and interior designers responding to the new absorber panel? Are you noticing growing interest in sustainable, acoustically effective products?

Yes, there is indeed a rapidly growing interest in sustainable solutions that are both functional and aesthetically appealing. Architectural firms and interior designers appreciate the combination of high acoustic effectiveness and an ecological concept that meets the requirements of modern building and room concepts. ABSORBER RECYCLED meets these expectations at a high level – not only through its high absorption coefficient, but also through its authentic, textile aesthetic, which can be harmoniously integrated into a wide variety of room concepts.

-

What next steps are you planning to take to integrate sustainability even more strongly into your product development and corporate philosophy?

Sustainability remains a dynamic process. We are continuously working to make our production processes even more efficient, increase the proportion of recycled materials in other product areas and further minimise our ecological footprint. In addition, we are committed to transparency, e.g. through environmental reports, and promote awareness of the circular economy among our partners and customers. In the future, we want to invest even more heavily in research and development of sustainable textile innovations – with the aim of consistently combining textile design with ecological responsibility.