Precision in every thread

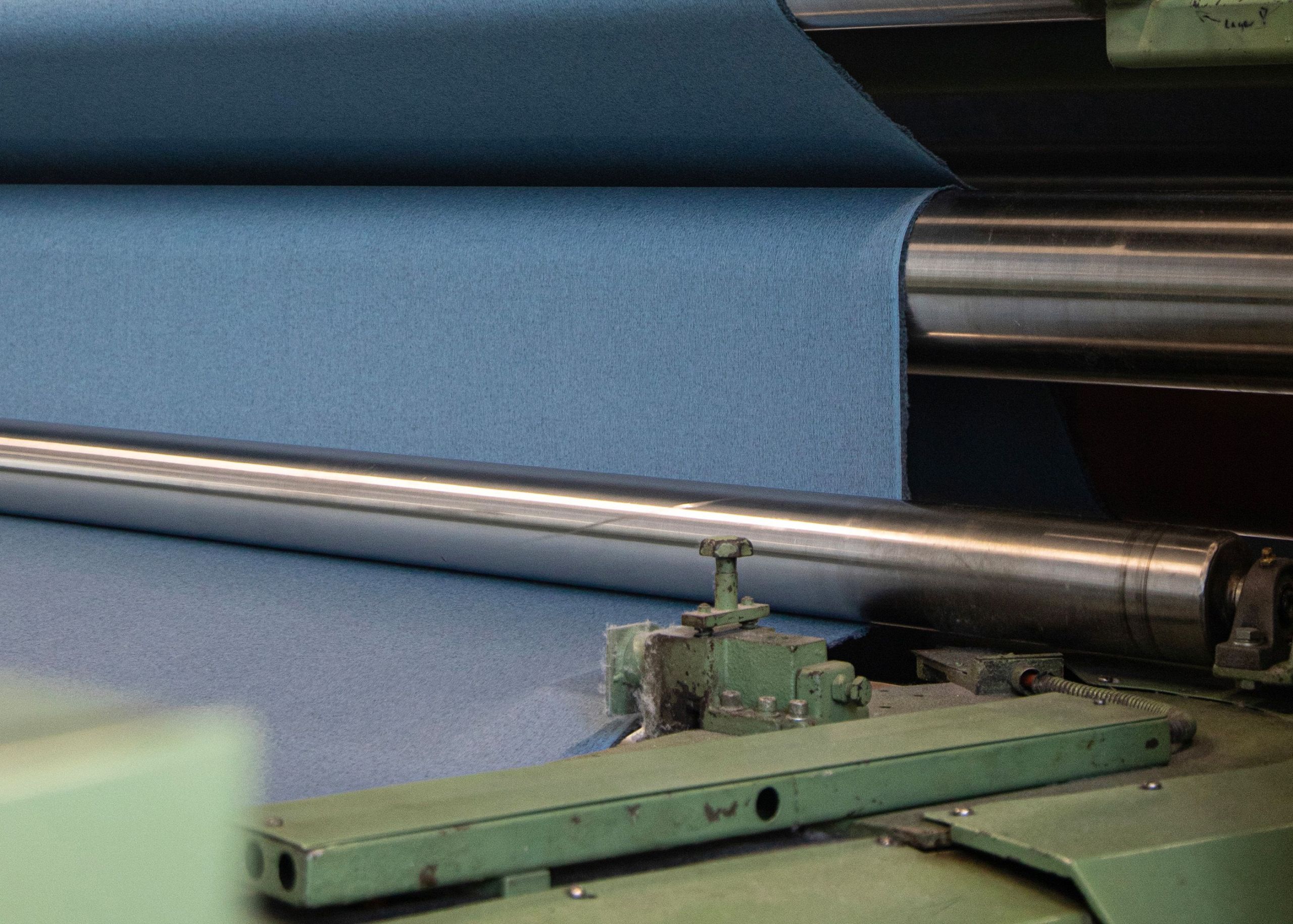

Our weaving mill and winding mill offer maximum precision and flexibility in textile production. In the winding department, yarns are prepared for dyeing and weaving on modern automatic winders to ensure smooth production.

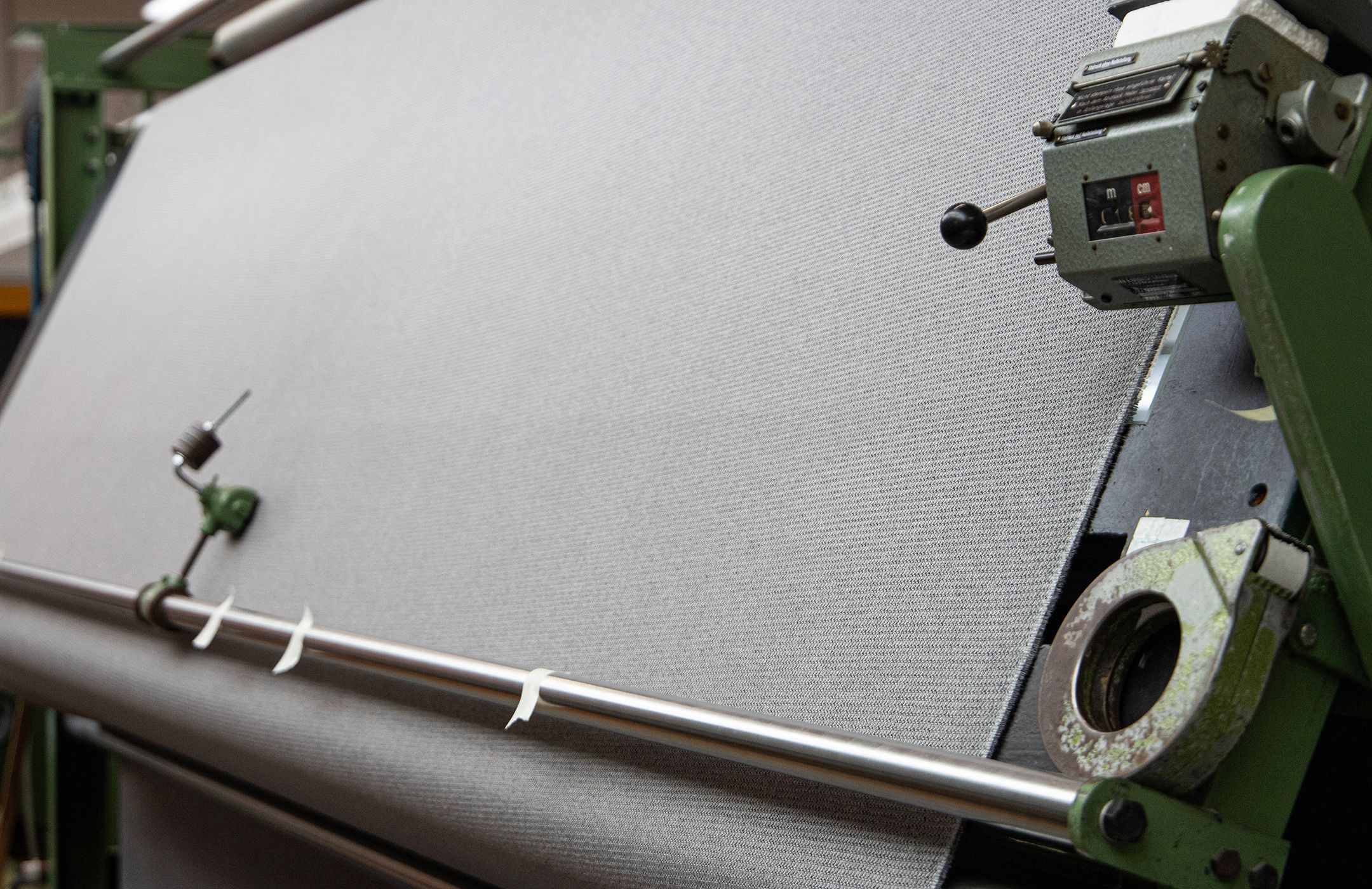

The loom weaving with a maximum weaving width of 330 cm produces dense and transparent fabrics, specialities such as leno and warp printed fabrics as well as custom-made products. With over 30 rapier weaving machines and electronic monitoring, the highest quality and efficiency are guaranteed.

Efficient processes and global shipping from Langenthal

Langenthal products reach over 40 markets worldwide, supported by efficient shipping and logistics.

In the area of fabric cutting, traditional craftsmanship is combined with modern technology. Our experienced team cuts fabrics precisely and individually according to customer requirements. Careful manual labour ensures maximum accuracy and flexibility in the customisation of fabrics.

The automatic packaging system ensures safe dispatch in environmentally friendly, recyclable packaging. Over 50,000 parcels and 20,000 boxes are dispatched worldwide every year.

Our logistics department ensures maximum efficiency through fast access and reliable availability of the product range.

Textile design made in Langenthal

216 employees are committed to innovative textile solutions with their expertise and great passion. Many of our textiles are produced entirely in our own factory in Langenthal – from design and yarn development to weaving and dyeing. Used as creative and functional long-lasting elements of interior design, they fulfil the requirements of functionality and design as well as the protection of people and the environment.